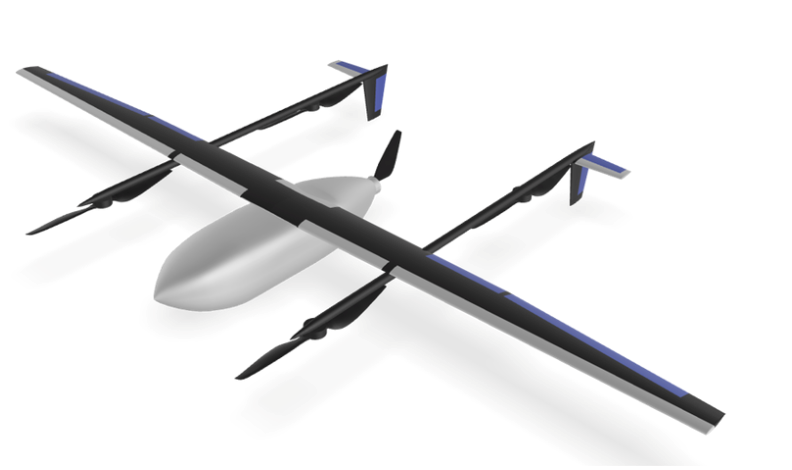

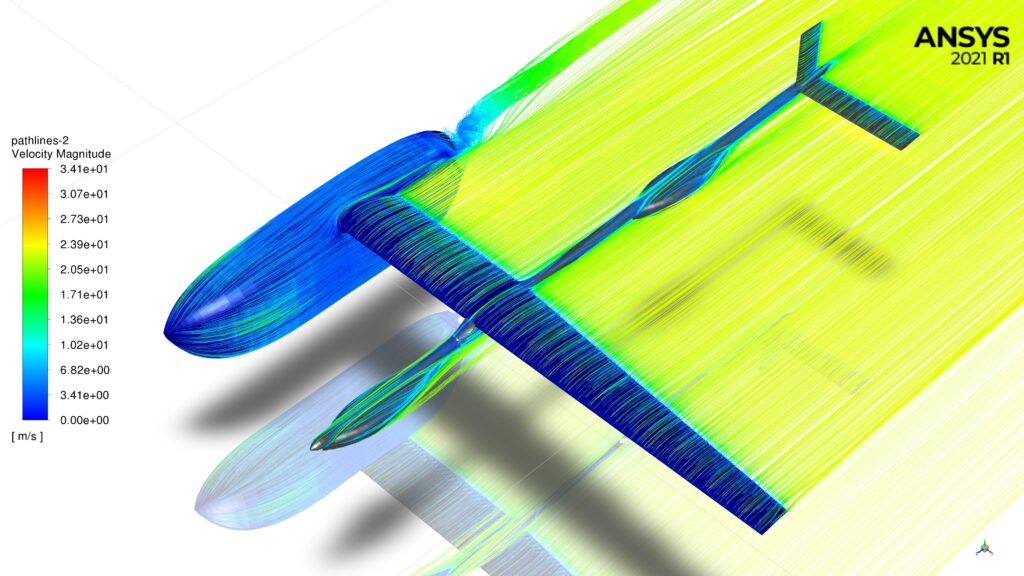

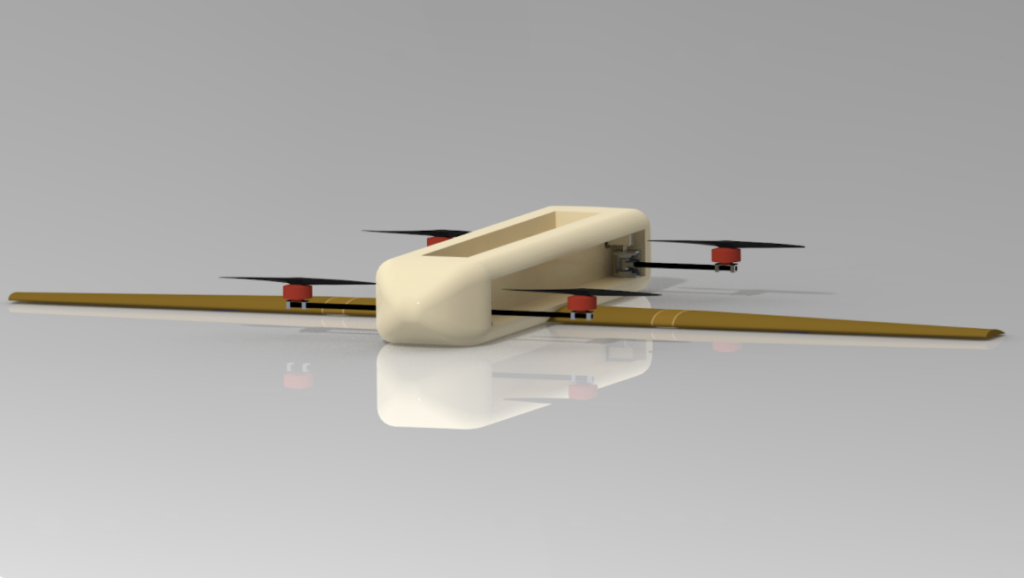

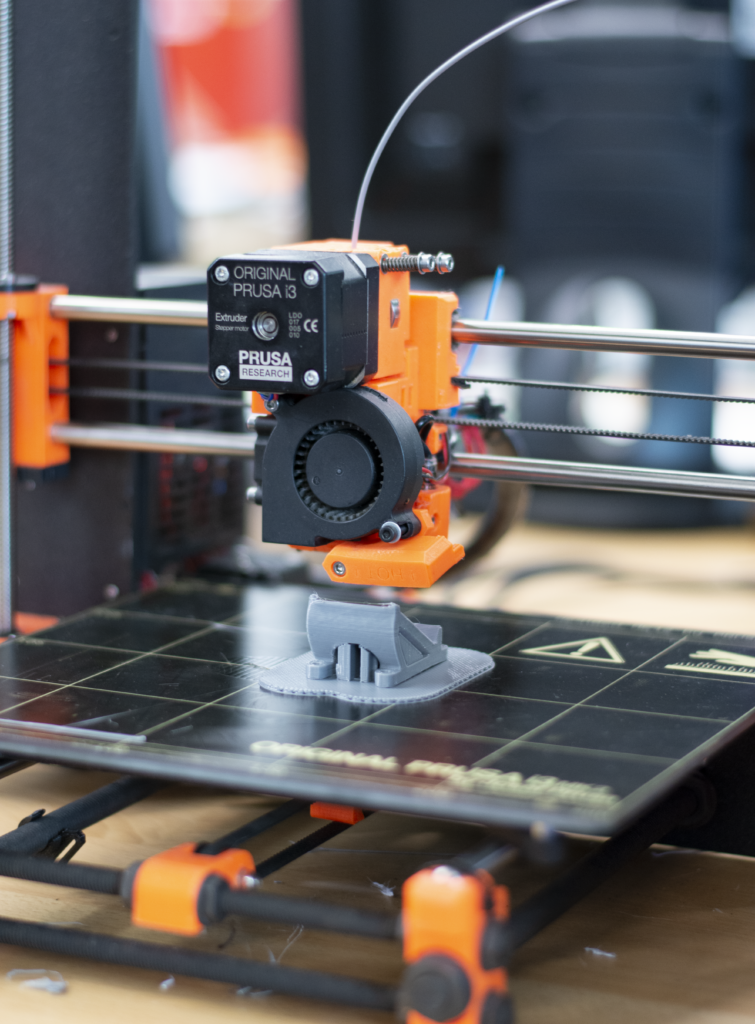

The Aerostructures team is responsible for the design, manufacture and maintenance of the Monash UAS airframes. The team utilises the latest composite technology and manufacturing techniques in order to produce aircraft that are lighter and stronger, while providing members of the team the opportunity to work with and learn about methods that are utilised more and more in the Aerospace industry.

section leads

Reuben Kobier